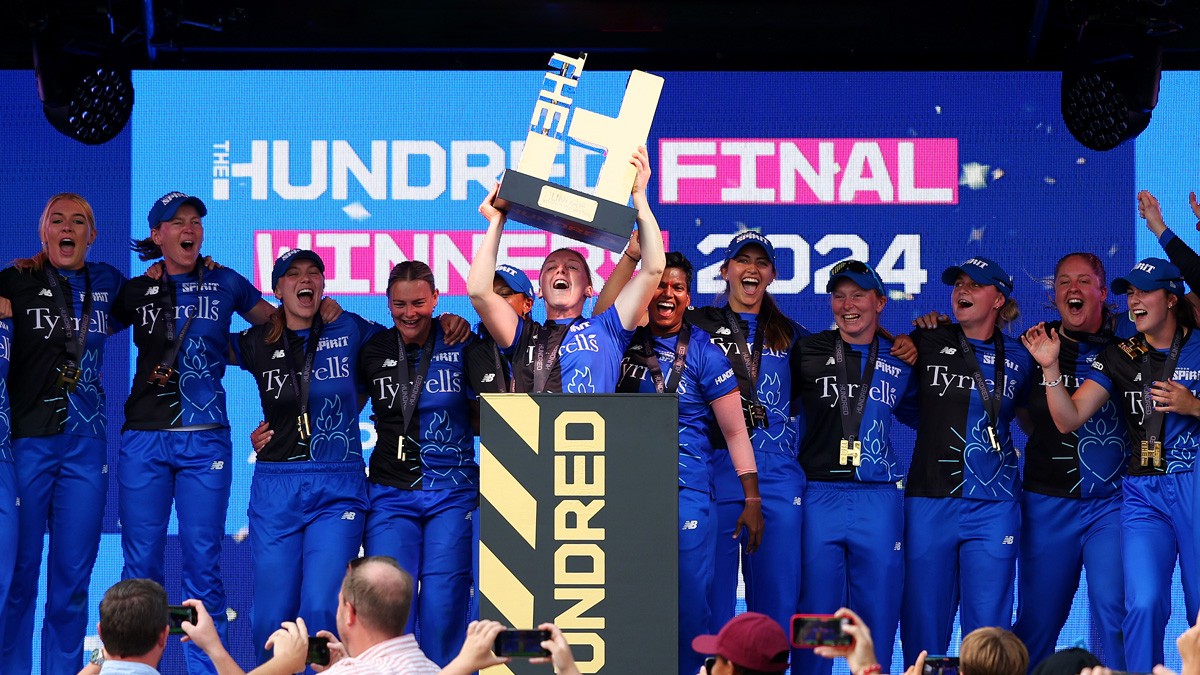

Graphene: How Manchester became home to a wonder material

A new generation of engineering companies is emerging in Manchester thanks to the extraordinary strength and elasticity of graphene

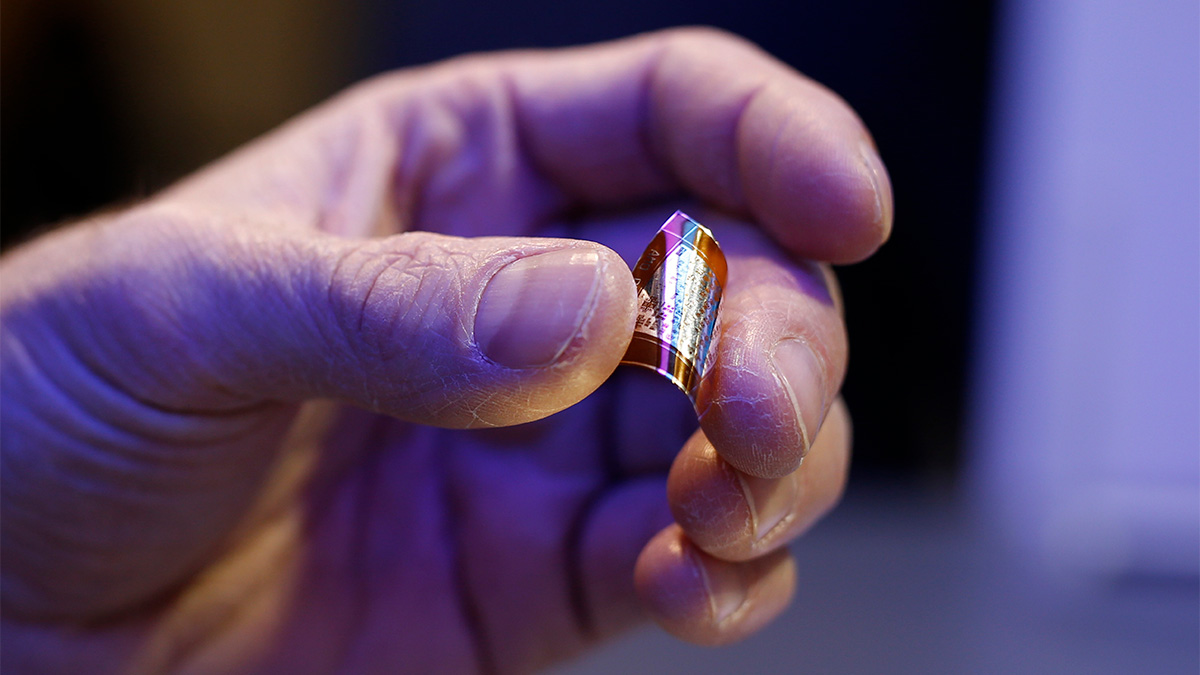

A graphene chip (Image: Pau Barrena/AFP via Getty Images)

A graphene chip (Image: Pau Barrena/AFP via Getty Images)

October 22, 2004, is etched into the memory of professors Andre Geim and Kostya Novoselov. That day, the two researchers at the University of Manchester were having one of their regular Friday night meet-ups, where they carried out experimental science not necessarily linked to their day jobs.

They removed some flakes from a lump of bulk graphite with sticky tape and noticed some flakes were thinner than others. It was the moment when the “wonder material” graphene was isolated for the first time. The discovery catapulted Geim and Novoselov to the world’s attention and, six years later, earned them the Nobel Prize in Physics.

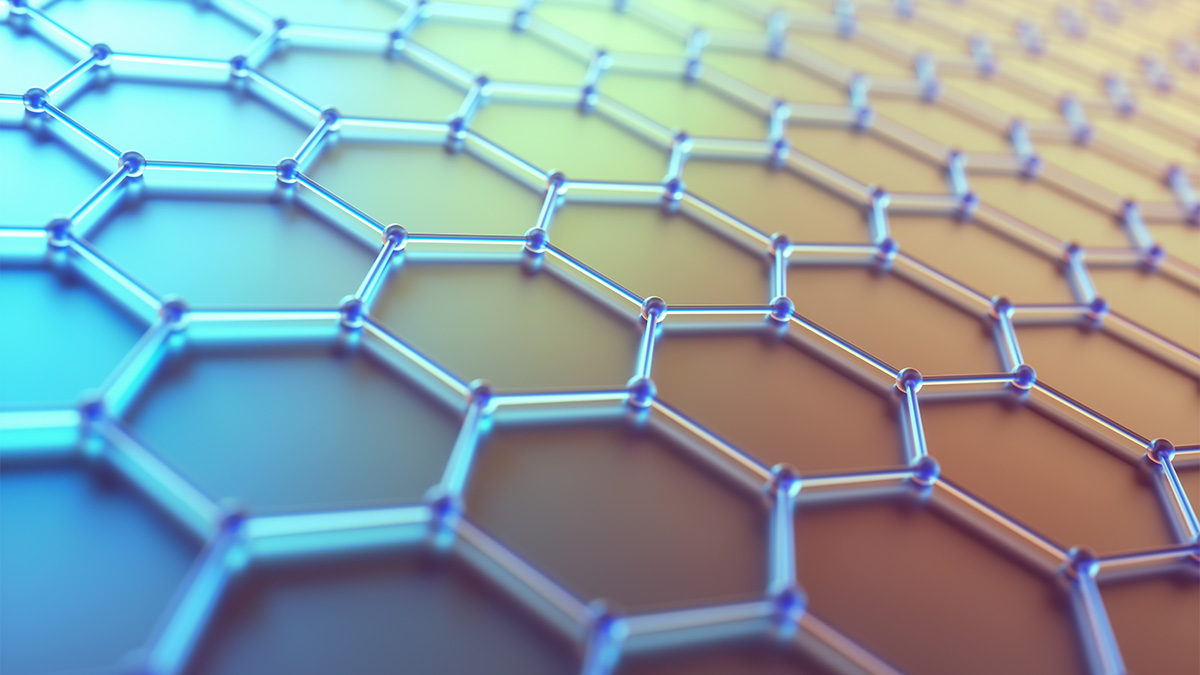

It also sounded the starting gun on a global race to commercialise graphene. Graphene is a single atomic layer of graphite, a crystalline version of carbon used in pencils, that is arranged in a hexagonal lattice. It is stronger than steel, more conductive than copper and more flexible than rubber. It is also so thin that it has been described as two-dimensional.

At the time, it was predicted that the miracle material would eventually become as common as plastic. And it has been used in everything from plane wings that can de-ice themselves to graphene-enhanced asphalt and treatments for patients with strokes and other brain disorders. But difficulties in producing graphene at an industrial scale mean its full potential is yet to be realised.

However, 20 years after it was discovered, many now feel use of the material is at a tipping point. And, fittingly, it is Manchester where many new game-changing graphene discoveries are taking place. In 2015, the £61m National Graphene Institute opened its doors. The research institute enables academics and industry to work side-by-side.

Four years later, the Graphene Engineering Innovation Centre (GEIC) was opened in the University of Manchester’s £60m Masdar Building. Since 2019 it has helped more than 55 new businesses to develop and launch new technologies, products and processes that make use of graphene.

The man tasked with overseeing the growth of the next generation of Manchester’s graphene companies is James Baker, chief executive of Graphene@Manchester. Describing itself as “industry-led, academic-fed”, GEIC is unique in UK academia.

Baker, who previously worked at BAE Systems, says: “People don’t come here to use graphene, they come here to solve their industrial challenges. We do things very quickly. Projects can last days and weeks rather than months and years. What we are really trying to do is accelerate the adoption of graphene and 2D materials.”

GEIC has helped develop several graphene products, including concrete that reduces CO₂ emissions by up to 30 per cent; a hydrogel for vertical farming; and a process to extract lithium from water for use in the battery-making industry. Its facilities are supported by a team of engineers and academics, helping companies design, develop, scale and de-risk new products and processes.

However, in a competitive global marketplace, the UK’s graphene industry is at a crossroads. Take the case of Dr Vivek Koncherry. He is chief executive of Graphene Innovations Manchester (GIM) and has been described by Baker as Manchester’s “answer to Elon Musk”.

The company connects graphene technology with business opportunities on a global scale. In 2023, Koncherry signed a $1bn (£800m) deal with Quazar Investment Company to create a company in the United Arab Emirates to help tackle global sustainability challenges.

In December 2024, during a visit to the Middle East, the prime minister Sir Keir Starmer announced that GIM had agreed to construct a factory in Saudi Arabia. This would be used to manufacture graphene for use in the country’s ambitious Neom giga-project, which plans to build futuristic eco-cities in the desert.

He also heralded the investment of around £250m in building a research and innovation hub in Greater Manchester that will create 1,000 jobs as part of the deal. That is good news for Manchester, but it could have been so much better. Koncherry had wanted to build a factory in Manchester but couldn’t attract the funding.

Koncherry came from India to study in Manchester in 2001 and quickly recognised the potential of graphene. “In the materials world, graphene is still new,” he says. “Most of the materials we use today, like carbon fibre, have existed for 50 or 60 years, while steel has been around for hundreds of years. It’s also one of the most advanced materials – it is a million times smaller than 1mm. It can be used in so many applications.”

GIM isn’t the only Manchester-based graphene company to attract attention. Vector Homes has been operating out of the GEIC for two years, making affordable smart homes from recycled materials.

The company uses nanomaterial-enhanced construction materials to minimise energy consumption during construction and throughout the lifespan of buildings. For example, it has built a prototype flatpack bungalow that incorporates graphene and can be built for a fraction of the cost of a more traditional house made of bricks.

Founder and chief technology officer Liam Britnell believes being based at GEIC has transformed the business. “Primarily it’s about speed,” he says. “We use a lot of different pieces of kit. If we wanted to buy that, it would be totally unfeasible. Here, you can access all that kit under one roof. Our ambition is to be delivering 5,000 homes a year within five years. In 10 years, I hope there isn’t a UK town that you’d drive through without seeing one of our products.”

Molymem is another GEIC tenant and is developing an energy-efficient membrane to create a water filtration solution that will result in cleaner water supplies. Its chief technology officer Paul Wiper says: “What’s been great about this facility is that we have access to state-of-the-art lab facilities. We can get access to equipment that can analyse and test our products on the same day, so we’re not relying on an external company. We can accelerate our product development by being at GEIC. It’s a great ecosystem where we can call on other experts.”

This is the magic of being based in Manchester, says Baker. Molymem was spun out of the university and has created a new business through GEIC. “They’ve managed to start, scale, get investment, win grants and get some real traction. GEIC has supported Molymem from start-up to scale-up.”

Manchester’s graphene reputation is also attracting international attention. Canadian-headquartered HydroGraph Clean Power, which manufactures graphene in the US, has chosen GEIC for an R&D facility. Another success story is Concretene, which is aiming to decarbonise the concrete industry through nanomaterial technology.

In 2024, the company secured £3m in venture capital investment to bring its graphene-enhanced concrete admixture to market. Cement production contributes more than 7 per cent of global CO₂ emissions, but Concretene can reduce those emissions significantly.

Crucially, Concretene is the first tenant of Manchester’s new innovation district. Known as Sister, it is a joint venture between the University of Manchester and Bruntwood SciTech, a property provider for the science and tech sector in the UK.

Previously known as ID Manchester, Sister will transform the university’s former North Campus into a four-million-square-foot innovation district that aims to help elevate Manchester’s position as a national centre for science and technology. Another piece of the jigsaw is Atom Valley, which includes a sustainable materials and manufacturing hub in Rochdale.

“It’s no coincidence that the National Graphene Institute and GEIC are based in Manchester,” says Baker. “This is the biggest graphene research and innovation community in the world for a reason – and it’s only getting bigger.”

Baker admits Manchester must continue developing graphene at pace or risk losing out to international rivals. “If we don’t do that, these companies are going to be attracted to the UAE, Saudi Arabia, Oman or China,” he points out. “What we’ve got here is an ecosystem that is growing, both in terms of people and skills, but also the knowledge of advanced materials and manufacturing that can really distinguish Manchester on the global map.”

Manchester needs to make sure it can translate its head start and focus on innovation into commercial success.